MYHB

Overview

MYHB Handling Unit by SEM is the new air handling unit generation designed to provide a top-level quality solution in HVAC for comfort, hospital, clean rooms, food industries and hygienic applications, able to offer, thanks to the flexibility in design and execution, unlimited solutions and wide range of airflow, capacity and options.

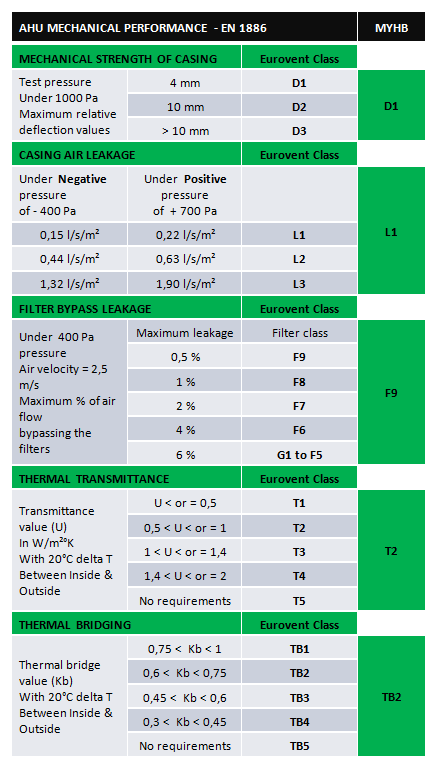

MYHB Air Handling Units are designed and manufactured in conformity with:

· EN 1886 e EN 13053 – casing classes and performances

· VDI 6022 (sheet 1) e DIN 1946 (part 4) – hygienic requirements

· Directive 2006/42/EC, 2014/30/EU

· Quality system EN ISO 9001:2015

Provided of pentapost construction, with aluminium perimetric frame and connections angles, is designed in 70 sizes with airflow range from 1.000 to 180.000 m3/h.

MYHB Air Handling Units are certified VDI 6022 (sheet 1) e DIN 1946 (part 4) for hygienic requirements and, thanks to continuous research of innovative solution, they are able to provide high air quality requirements to offer a safe and comfortable environment.

Materials: special materials and surface treatment are available, providing chemical resistance or hygienic execution of the unit.

Options stainless steel construction (components fully made in 304 or 316 stainless steel) or epoxy painted are available.

Air tightness of the casing: Certified L1 EN 1886, reduces the air leakage of non treated air.

High filter air tightness: Certified F9 EN 1886 The filter is locked in a frame with gasket preventing the air bypassing the filter.

Inclined drain pan: cooling coil and humidifier are provided with fully insulated stainless steel drain pan, 4-slopedwith bottom drain in the lowest point. Drain pans can be optionally provided in all the sections.

Internal cleaning: the internal parts of the unit are perfectly smooth. There is no use of internal screws ore bolts avoiding any dirty and dust accumulation, assuring a high grade of hygiene. Air Handling Units are provided of removable panels, this solution provides a full accessibility of the internal components for maintenance and cleaning.

Removable components: in all the units, coils and humidifiers are mounted on rail to be easily removed.

As option, all other components can be installed on rail for fast and easy removal.

Easy assembly and full accessibility: MYHB Air Handling Units can be supplied in monoblock or in modular sections; if provided in sections an easy, fast and fully reliable connection system is provided, assuring best in class air tightness and avoiding leakage of not treated air.

Thanks to pentapost construction, is section is fully accessible from the inspections doors or by easy and full casing removal.

MYHB Air Handling Units have been designed to assure high operating efficiency end energy recovery, thanks to the smooth surface of the unit low air velocity and low pressure drops are possible. The result is a low Specific Fan Power and high energy class. Thanks to the wide range of options of fans, size, types, variable frequency driver, a most reliable and efficient working condition is in reach. The MYHB casing allows a low air leakage and a very high thermal insulation, the design is in line with the international standards and is certified. The units are fully energy efficient.

The casing of MYHB Air Handling Units is manufactured using a patented new concept, made by aluminium framework and nylon corners, no welding, assuring high corrosion resistance.

In addition to the feature of the casing of MYHA, MYHB Air Handling Units is provided of special insert able to create an important thermal break, increasing the thermal insulation of the casing and reducing thermal bridge.

The sandwich panels are assembled using wedge and gasket, providing a high external and internal finishing and smoothness, high air tightness and fully accessibility. Panels are provided with different materials galvanized steel, painted steel, peraluman, 304 and 316 stainless steel, thickness of the metal sheet from mm.0.6 to mm.1.0 and panel thickness of mm. 50 or 60.